'OFB20' Further 20% OFF Sale | free shipping Australia wide

'OFB20' Further 20% OFF Sale | free shipping Australia wide

Accessories

Check out our full lineup of yoga accessories to help you with your daily meditation practice and fitness goals...

Try our new Cork Yoga Brick for soft but solid support

Check out our full lineup of yoga accessories to help you with your daily meditation practice and fitness goals...

Keep Curios About Circularity

4 min read

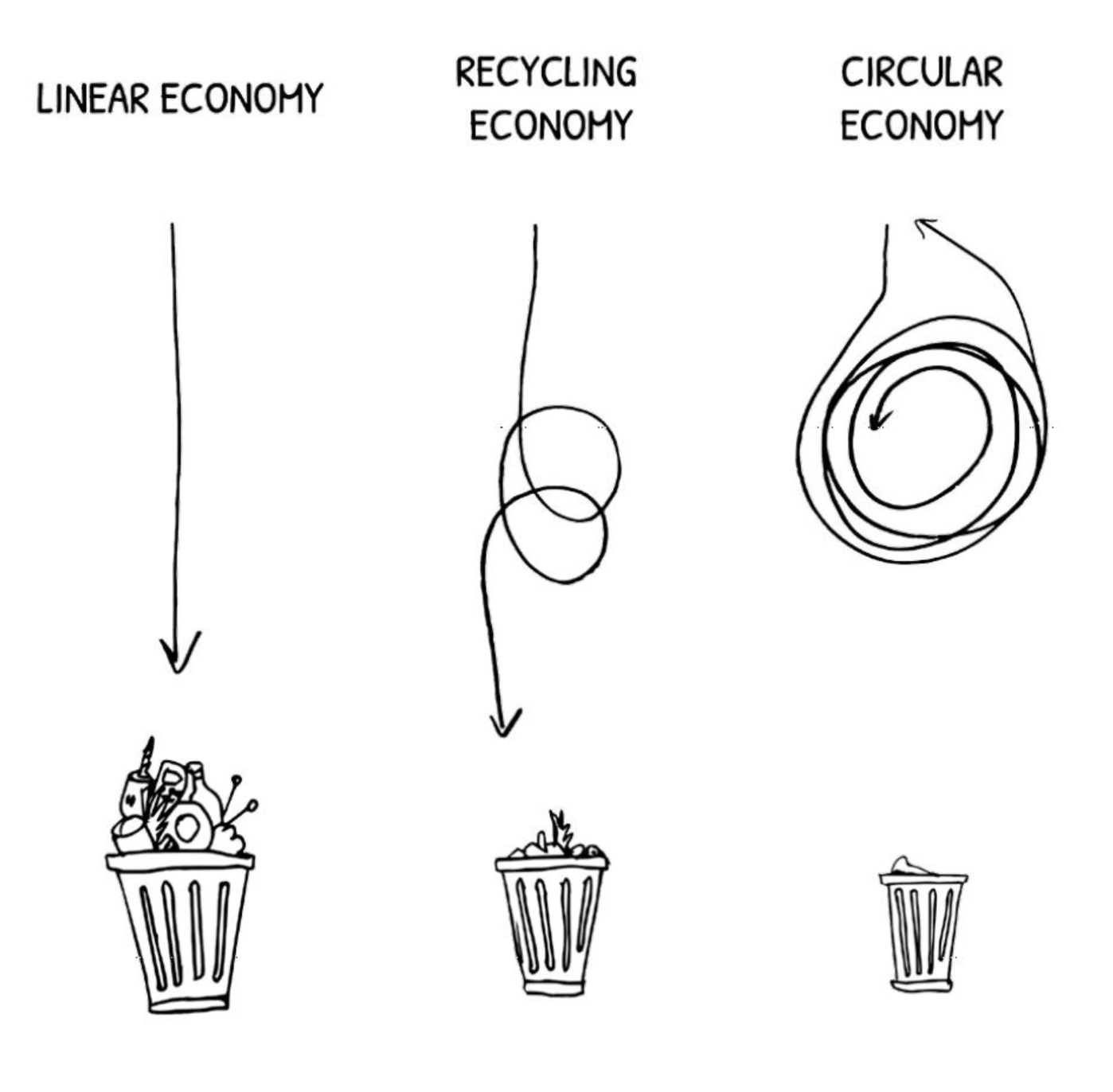

The values and vision for Tyoub have always been driven by the desire to produce sustainable and distinctively high-quality children’s swimwear. The challenge for Tyoub is always the same to satisfy the three pillars of Functionality, Sustainability and Desirability. In the hours of constant reading, research and data analysis of the fashion industry, the pursuit of creating a business that “closes the loop” has become increasingly important to us. And so it has been a slow and steady path forward, as we move deliberately towards a circular and a greener fashion footprint. We are not always 100% right, but we are 100% committed to constantly improving.

This year has been an exciting year of serendipitous meetings and the universe has really conspired to bring the knowledge to the seeker. It began in earnest at the inaugural Australian Circular Fashion Conference. It was a fascinating day with world class speakers from leading on environmental fashion brands; Eileen Fisher, Mara Hoffman and FilipaK. The compelling presentation by industry experts speaking about fashion pollution in land, water and air by Christian Dreszig from Bluesign technologies stating “The quality level of circular economy matters”. The facts startling, frightening and obvious to everyone there, that a fashion revolution is what’s needed and inevitable. There were so many take-aways from the presenters and we can’t wait to attend in 2020.

Before attending the conference, we had come across a research project that had won an H&M Foundation award for denim production by the Institute for Frontier Materials at Deakin University, in Geelong undertaken by Professor Xungai Wang and his fellow researchers. The denim research is brilliant, even though Tyoub is a swimwear brand and we focus on synthetic fibres so meeting the experts from The Australian Future Fibres Research and Innovation Centre was marvellous.

Through this meeting we were invited to the first of a series of lectures from Deakin University and the City of Geelong titled A Clever and Creative Future. The presentation that really struck me was given by professor Matthew Barnett who addressed two key areas that are vital to achieving a circular economy, product design and material design. Professor Barnett used the analogy of a toaster in three design scenarios.

Example 1. The Indestructible Toaster. Made of aluminium with a single function easy to repair commercial style toaster. Ticking all the boxes at first glance, it’s designed to last, made from recyclable material and can be repaired. This toaster will last a life time!

Example 2. The Modular Toaster. This theoretically would come as a set of components whereby the consumer can add on extra slices as needed taking it from a 2 slice to 8 slice toaster, by clipping on additional parts. The manufacturer has a return model for recycling parts and are therefore closely monitoring the product, which addresses the life cycle assessment of toaster and stewardship of the disposable parts.

Example 3. The Cheap and Cheerful Toaster. This toaster is made to be recycled, the toaster is designed to blow apart and easily disassemble in a low pressure recycling chamber. It is basically a fast fashion toaster!

As obvious from these examples, so many questions can be asked and a great deal of insight and understanding into consumer intelligence and behaviour can be gleaned. We like to break these down into four pillars; Production, Distribution, Consumption and Rebirth. As Tyoub is a swimwear brand we are going to move swiftly forward to The Future Fibres Hub.

After a few email exchanges with the very generous and helpful Dr Marzieh Parhizkar we were invited to visit the Geelong Waurn Ponds Campus and the Institute for Frontier Materials. We had the wonderful opportunity to present and discuss Tyoub’s reusable swim nappy and the material life cycle of the swim nappy that we have prototyped and produced. We know that 80% of environmental impact is decided at the design stage and being an independent brand we have the advantage of flexibility at design stage. We also wanted to closely look at artificial, recycled, changeable and experimental material for children’s wear in a broader range of activewear. We are also committed to using regenerated fibres for our swimwear range and have chosen to partner with Aquafil who produce ECONYL® - a premium regenerated polyester and nylon LYCRA® from recycled ocean fishing nets and post-consumer plastics.

We presented our reusable swim nappy to eight of the most brilliant textile engineers and researchers. The range and depth of their collective knowledge is outstanding. The highlight of our day was a tour of the laboratory and viewing IFM’s equipment including an electron microscope and atom probe. IFM is on a mission to “re-design materials for a circular economy” and “impart materials with extraordinary functionality” this to me is both inspiring and encouraging.

The Future Fibres Hub at Deakin University are open and welcoming to industry partnerships and work with brands such as Draggin jeans and HEIQ materials, as well as 50 active industry partners in 10 countries. This is a world class facility on our doorstep! For Tyoub this would be the ultimate collaboration and is what we work towards achieving every day. It is only through excellent research, innovation and the industry’s ability to scale up the ideas from the laboratory that circularity can be achieved. We hope that IFM might be presenting at the next Australian Circular Fashion Conference, because that would certainly be invigorating to the fashion industry in Australia.

Circular Economy Graphic credit to Circular Flanders community

Premium. Ethical. Sustainable. Kids. Swimwear.

Tyoub, eco-friendly swimwear brand based in Melbourne, Australia. Offering reusable swim nappies for toddlers and babies. The best bathers and swim togs for children. Year round swim essentials to help parents navigate weekly swimming lessons and hassle free holidays. Conscious swimwear made with recycled polyester motivated by marine conservation.